- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

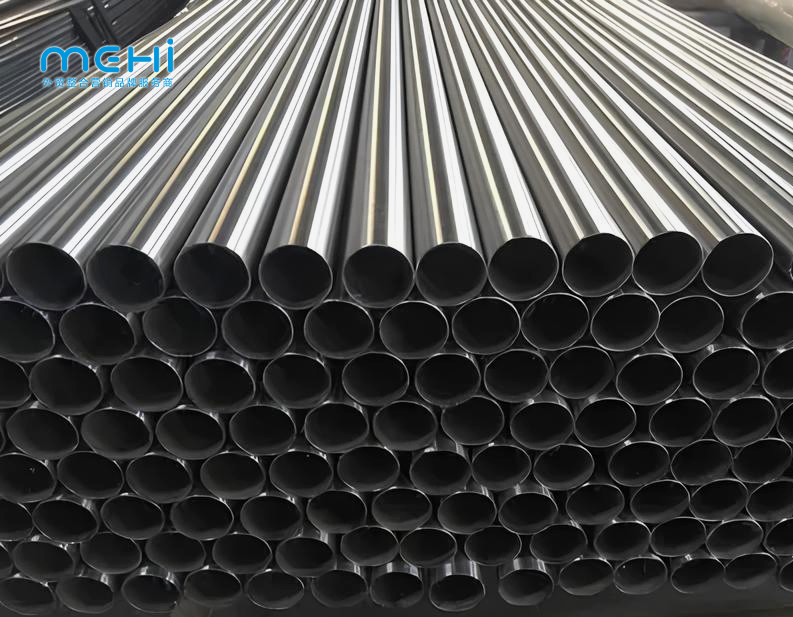

Nickel 200 Tubing

Grade: Nickel 200 (UNS N02200)

Standard: ASTM B161, ASME SB161, DIN 17750

OD: 6.0-114 mm

WT: 0.5-15 mm

Length: Max 15000 mm

Customization and processing supported

Surface treatments:Sandblasting/Anodizing

Material Certification: MTC and SGS test reports available

Provide Free sample

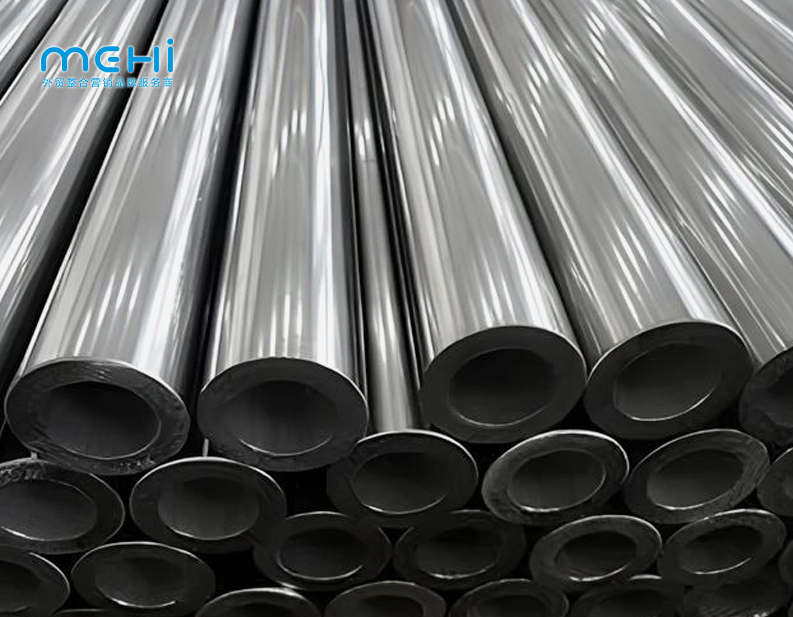

Nickel 200 Tubing: Premium Corrosion-Resistant Solution for Industrial Applications

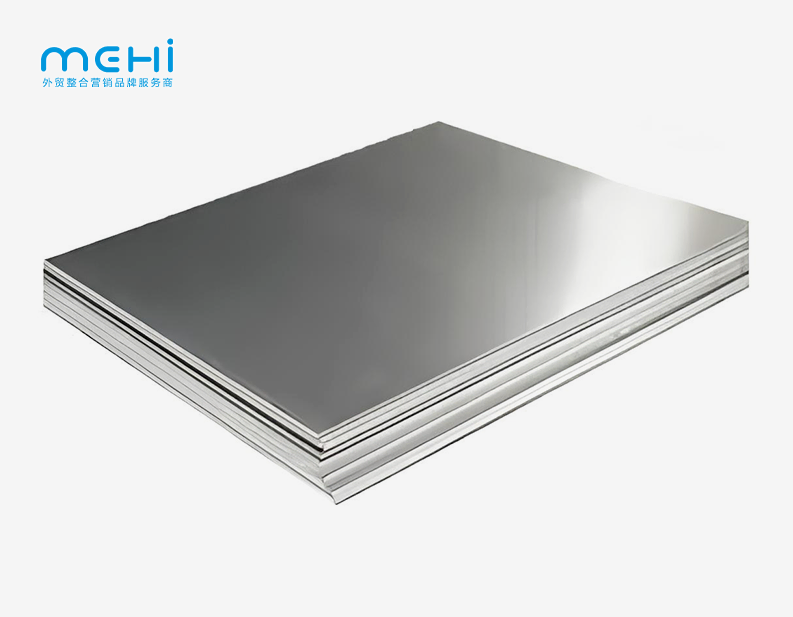

When you need reliable, high-performance tubing for demanding industrial environments, Nickel 200 Tubing delivers exceptional corrosion resistance and durability. Our commercially pure nickel tubing offers outstanding performance in chemical processing, marine applications, and high-temperature environments where standard materials simply won't suffice. With 99.6% minimum nickel content, this tubing provides superior resistance to caustic solutions and maintains excellent mechanical properties across a wide temperature range. You'll find our tubing meets the most stringent industry requirements while offering long-term reliability for your critical applications.

Superior Material Properties You Can Trust

Our pure nickel tubing excels in environments where other materials fail. The exceptional corrosion resistance makes it perfect for chemical processing equipment, pharmaceutical manufacturing, and marine applications. You benefit from excellent thermal conductivity and magnetic properties that remain stable even under extreme conditions.

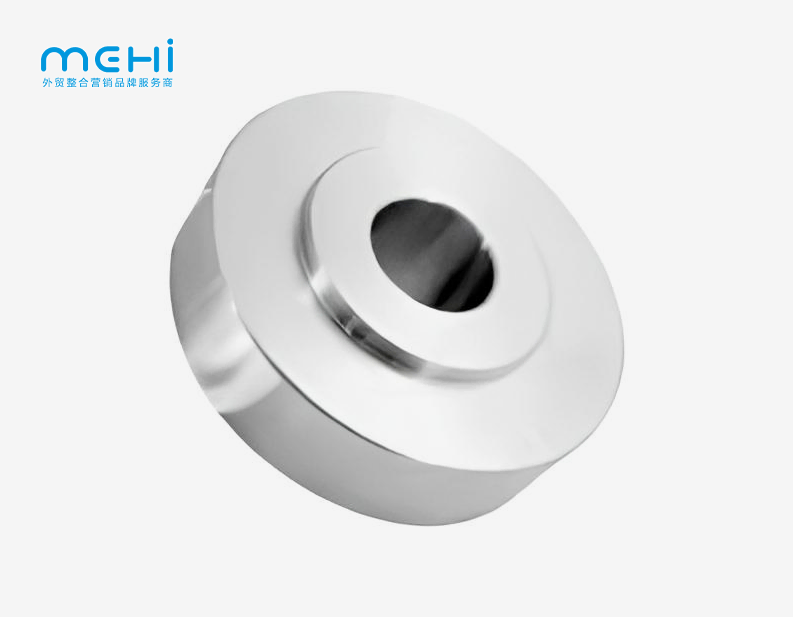

The material's outstanding ductility allows for complex forming operations without compromising structural integrity. This flexibility means you can achieve intricate designs while maintaining the tube's protective qualities. Whether you're working with caustic chemicals or high-temperature processes, this material maintains its performance characteristics.

Technical Specifications That Meet Your Needs

Grade: Nickel 200 (UNS N02200)

Standards: ASTM B161, ASME SB161, DIN 17750

Outside Diameter: 6.0-114 mm

Wall Thickness: 0.5-15 mm

Maximum Length: 15,000 mm

Our manufacturing capabilities include three dedicated factories with eight production lines and over 100 specialized machines. This extensive infrastructure ensures consistent quality and reliable delivery times for your projects. We support complete customization and processing to meet your specific requirements.

Quality Assurance and Surface Treatment Options

Every piece of tubing undergoes rigorous quality inspection using advanced testing equipment. Our professional inspection team ensures each product meets international standards before shipment. You receive comprehensive material certifications including MTC and SGS test reports with every order.

Surface treatment options include sandblasting and anodizing to enhance performance and appearance. These treatments improve corrosion resistance and provide better adhesion for subsequent coatings when required. Our Nickel 200 Tubing maintains its superior properties regardless of the surface treatment applied.

Applications Across Multiple Industries

Chemical preparing plants depend on our tubing for taking care of destructive media and high-purity applications. The pharmaceutical industry employments it for hardware that requires outright cleanliness and chemical compatibility. Marine situations advantage from its great resistance to seawater corrosion.

Oil and gas operations select this fabric for seaward stages and handling gear where unwavering quality is basic. Restorative gadget producers appreciate its biocompatibility and sterilization resistance. Nourishment preparing offices utilize it for hardware that requests both sterile conditions and chemical resistance.

Manufacturing Excellence and Customer Support

Our strict raw material procurement standards ensure quality from the source. We partner only with verified suppliers who meet our demanding specifications. Advanced production equipment and process technology guarantee consistent results across all production runs.

Fine production process management includes continuous monitoring of each manufacturing stage. This attention to detail ensures your product meets exact specifications every time. Our commitment to quality means you can rely on consistent performance for your most demanding applications.

Get Your Free Sample Today

Experience the quality difference for yourself with our complimentary sample program. We understand that material verification is crucial for your projects, so we provide free samples to qualified customers. This allows you to test the material's performance in your specific application before placing larger orders.

Ready to discuss your Nickel 200 Tubing requirements? Contact our experienced team at somyshare@gmail.com for personalized assistance with your next project. We're committed to providing the high-quality materials and expert support you need for success.