- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

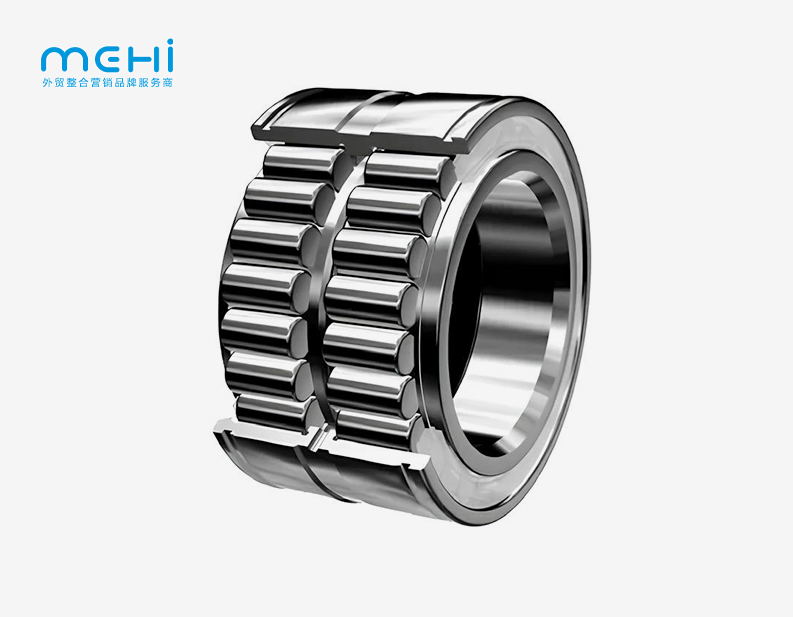

Double Row Cylindrical Roller Bearing

The NNU design has an inner ring without ribs and an outer ring with two ribs.

2. Advantages: The advantages of the double-row cylindrical roller bearings are high stiffness and high precision.

3. Application: They are usually used as main shaft bearings of precision machine tools.

4. Size range:

Inter diameter:200-1500mm

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

6. Feature:

The double-row cylindrical roller bearing is one separable type bearing and easy to assemble and disassemble.

The double-row cylindrical roller bearing has two optional structures: cylindrical bore and tapered bore(suffix K).The tapered bore structure can allow the radial clearance to be adjusted when the bearing is installed. The double-row cylindrical roller bearing allows a certain axial displacement between the shaft and bearing housing and can be used as a non-locating bearing.

Double Row Cylindrical Roller Bearing - High Performance Industrial Solution

When you require solid execution beneath extraordinary conditions, our Double Row Cylindrical Roller Bearing conveys uncommon comes about. These heading include two parallel columns of round and hollow rollers that work together to handle enormous outspread loads with exceptional accuracy. At MEHI Supply Chain Company, we've designed these heading to surpass your desires in the most requesting applications. Our progressed fabricating handle guarantees each bearing meets strict quality guidelines whereas giving the strength you require for nonstop operation.

You'll appreciate the predominant plan that combines tall stack capacity with extraordinary unbending nature. The double-row arrangement disperses weight equally over both roller sets. This implies longer benefit life and decreased support costs for your hardware.

Key Features and Benefits

High Load Capacity Performance

Our bearings support heavy radial loads that would overwhelm standard single-row designs. The dual-row structure increases load distribution by up to 80% compared to conventional bearings.

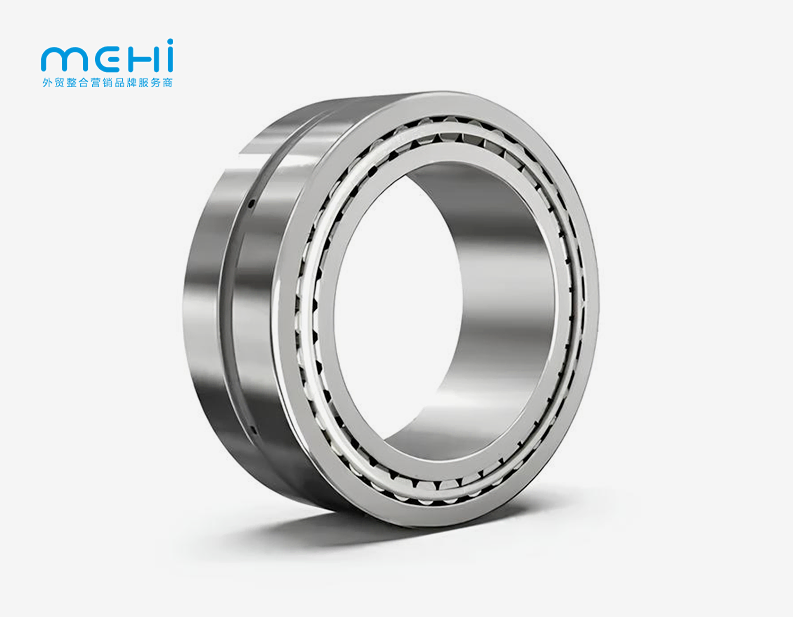

Enhanced Rigidity and Stability

You get superior stability under high-stress conditions. The robust construction minimizes deflection and maintains precise positioning even under extreme loads.

Separable Design Advantage

Installation and maintenance become much easier with our separable bearing design. You can remove and replace components without dismantling entire assemblies.

Flexible Bore Options

Choose between cylindrical bore or tapered bore (suffix K) configurations. The tapered bore option allows you to adjust radial clearance during installation for optimal performance.

Axial Displacement Capability

These bearings accommodate shaft movement and thermal expansion. This flexibility prevents binding and extends operational life in varying temperature conditions.

Technical Specifications

Available Series:

- NN Series: Inner ring with two ribs, outer ring without ribs

- NNU Series: Inner ring without ribs, outer ring with two ribs

Size Range:

- Inner diameter: 200-1500mm

- Custom sizes available upon request

Premium Materials:

- GCr15 steel for standard applications

- GCr15SiMn for enhanced performance

- G20Cr2Ni4A for specialized requirements

Industrial Applications

Precision Machine Tools

Your CNC machines and precision equipment benefit from the exceptional accuracy Double Row Cylindrical Roller Bearing provides. They maintain tight tolerances even under continuous operation.

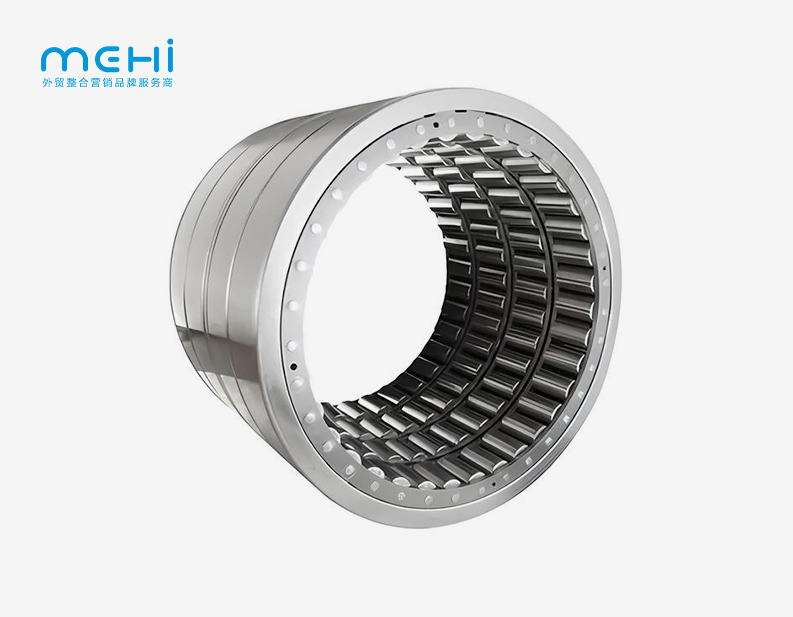

Metallurgical Equipment

Rolling mills, blast furnaces, and steelmaking machinery operate more reliably with our heavy-duty bearing solutions.

Mining Machinery

Crushers, vibrating screens, and conveyor systems handle increased throughput with reduced downtime.

Heavy Industrial Equipment

Large rotating machinery in power generation, cement production, and paper mills achieve improved performance and longevity.

Why Choose MEHI Supply Chain Company?

We bring over 150 sets of advanced production equipment and 70+ precision testing instruments to every bearing we manufacture. Our facility produces 30,000 sets of long-life mill bearings annually, ensuring consistent availability for your projects.

Quality control runs through every step of our process. We use CMM, metallographic microscopes, roundness meters, and friction torque testers to verify each bearing meets exacting standards.

Our engineering team continuously develops innovative solutions for challenging applications. From design consultation to after-sale support, we're committed to your success.

Get Expert Guidance Today

Ready to upgrade your equipment with premium Double Row Cylindrical Roller Bearing solutions? Our technical specialists help you select the right bearing configuration for your specific requirements.

Contact us at somyshare@gmail.com for detailed specifications, custom sizing options, or technical consultation. We'll work with you to ensure optimal bearing selection and installation success.