- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

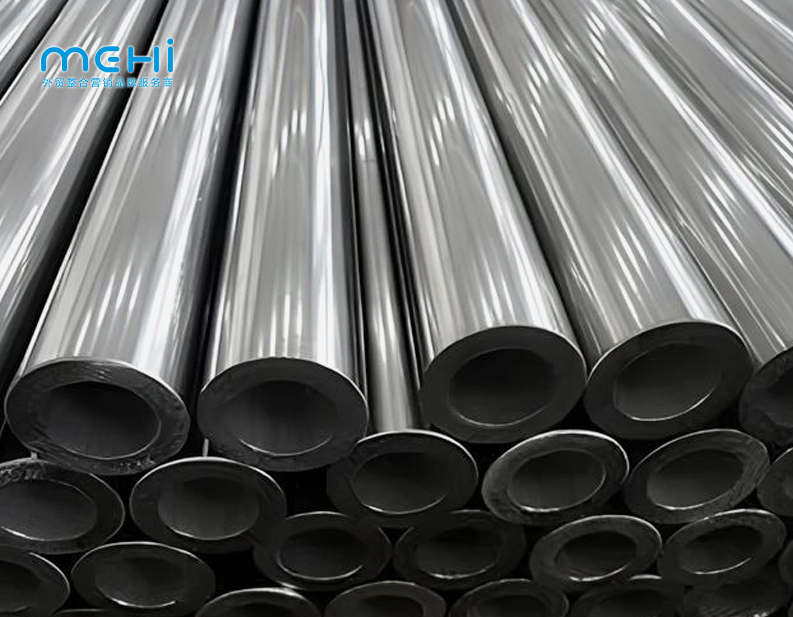

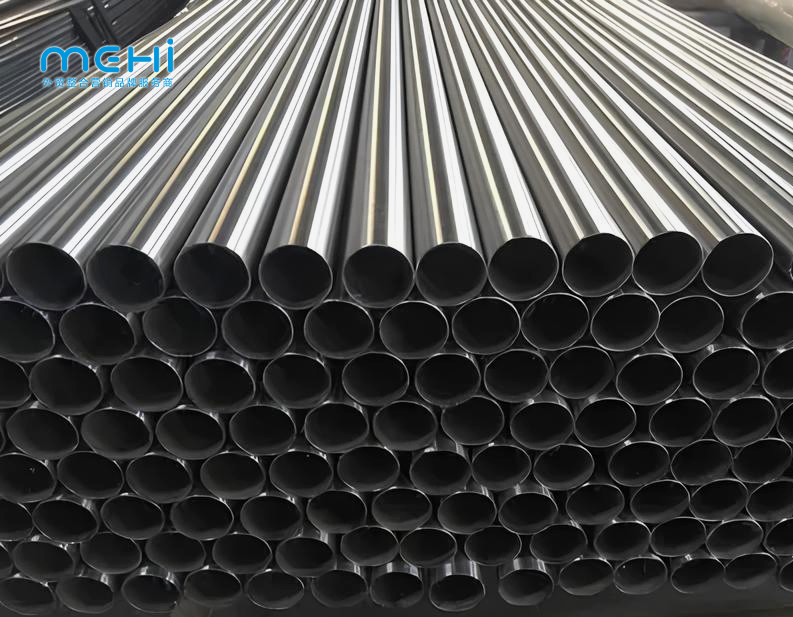

Alloy 200 Tubing

3 factories*8 production lines*100+ machines

Grade: Nickel 200 (UNS N02200)

Standard: ASTM B161, ASME SB161, DIN 17750

OD: 6.0-114 mm

WT: 0.5-15 mm

Length: Max 15000 mm

Customization and processing supported

Surface treatments:Sandblasting/Anodizing

Material Certification: MTC and SGS test reports available

Provide Free sample

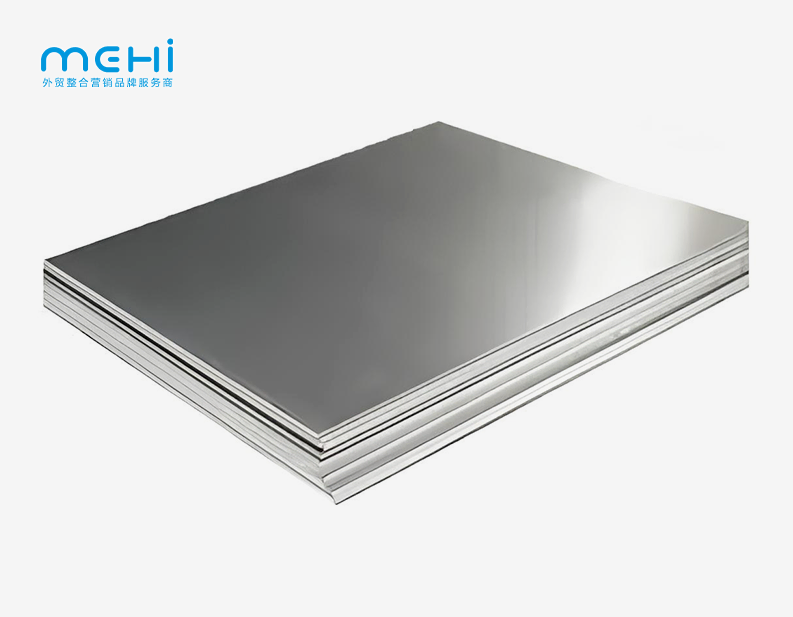

High-Performance Alloy 200 Tubing for Industrial Applications

When your project demands exceptional corrosion resistance and superior nickel alloy performance, Alloy 200 Tubing delivers unmatched reliability. This premium nickel tubing solution offers outstanding mechanical properties and chemical resistance across diverse industrial applications. Our high-quality tubing meets stringent industry standards, ensuring optimal performance in challenging environments. You'll find this commercially pure nickel tubing ideal for chemical processing, electronics, and caustic applications where material integrity matters most.

Why Choose Our Nickel 200 Tubing?

Exceptional Material Properties

Our nickel tubing shows exceptional erosion resistance, especially in soluble situations. You'll appreciate its great warm and electrical conductivity, making it culminate for warm exchangers and electronic components. The fabric keeps up basic astuteness over wide temperature ranges, from cryogenic conditions to raised temperatures up to 315°C.

Superior Manufacturing Standards

TSM Technology brand tubing comes from our three dedicated factories featuring eight production lines and over 100 precision machines. We manufacture according to ASTM B161, ASME SB161, and DIN 17750 standards, ensuring consistent quality you can trust.

Comprehensive Size Range

Our tubing specifications include:

- Outer Diameter: 6.0-114 mm

- Wall Thickness: 0.5-15 mm

- Maximum Length: 15,000 mm

- Grade: Nickel 200 (UNS N02200)

Advanced Quality Control System

Strict Raw Material Selection

We partner exclusively with premium raw material suppliers who meet our rigorous quality standards. This careful selection process ensures your tubing starts with the finest nickel alloy materials available.

Precision Manufacturing Process

Our advanced production equipment and cutting-edge process technology guarantee exceptional product consistency. Every production stage undergoes strict monitoring and management, delivering Alloy 200 Tubing that exceeds industry expectations.

Comprehensive Inspection Protocol

Our proficient assessment group employments state-of-the-art testing hardware to look at each angle of your tubing. This careful quality affirmation handle recognizes and settle any potential issues some time recently shipment.

Versatile Industrial Applications

Chemical Processing Industry

The excellent caustic resistance makes our tubing ideal for sodium hydroxide production, chlor-alkali plants, and various chemical processing applications where corrosion resistance is critical.

Electronics and Electrical

Superior electrical conductivity and thermal properties make this tubing perfect for electronic components, vacuum tubes, and electrical applications requiring reliable performance.

Food and Pharmaceutical

The material's purity and corrosion resistance ensure safe contact with food products and pharmaceutical compounds, meeting strict industry hygiene standards.

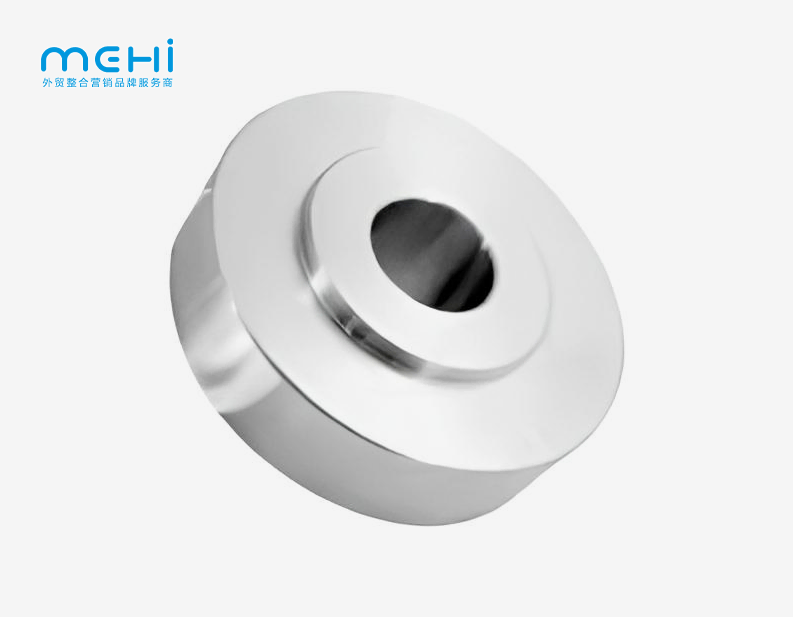

Custom Solutions Available

We understand that standard dimensions don't always meet specific project requirements. Our customization services include:

- Custom sizing to match your exact specifications

- Specialized processing for unique applications

- Surface treatments including sandblasting and anodizing

- Modified lengths up to our maximum capabilities

Quality Certifications and Testing

Every shipment includes comprehensive material test certificates (MTC) and SGS test reports, providing complete traceability and quality assurance. These certifications verify chemical composition, mechanical properties, and dimensional accuracy.

Free Sample Program

We're confident in our product quality and offer free samples for evaluation. This allows you to verify material properties and dimensional accuracy before placing larger orders.

Technical Support and Expertise

Our experienced team provides comprehensive technical support throughout your Alloy 200 Tubing project. From material selection to application guidance, we ensure you receive the optimal tubing solution for your specific requirements.

Ready to experience superior nickel tubing performance? Contact our technical specialists at somyshare@gmail.com for detailed specifications, custom quotes, or free samples. Let us help you find the perfect tubing solution for your next project.