- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Single Row Cylindrical Roller Bearing

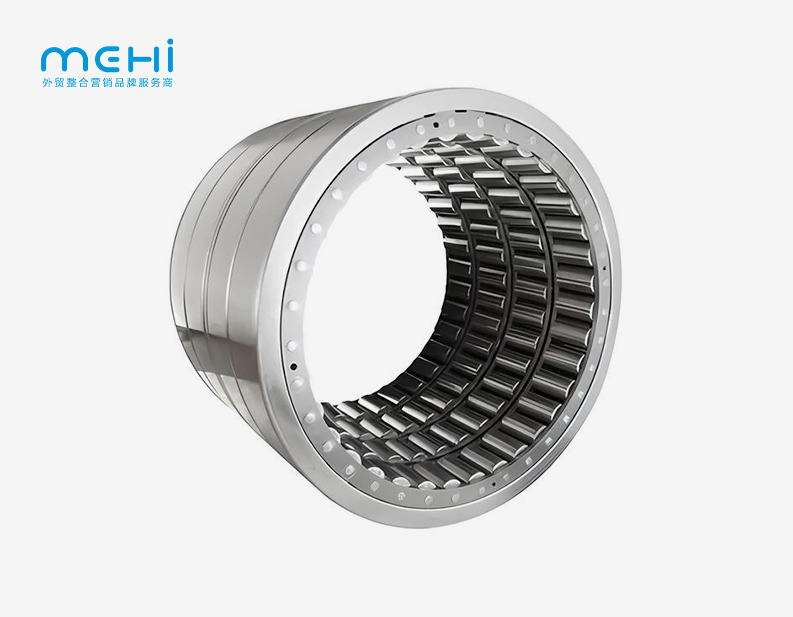

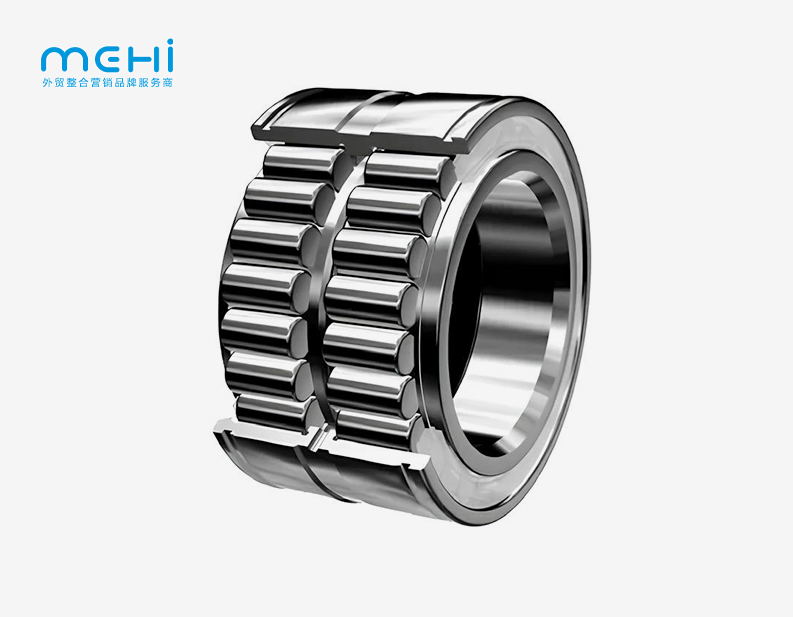

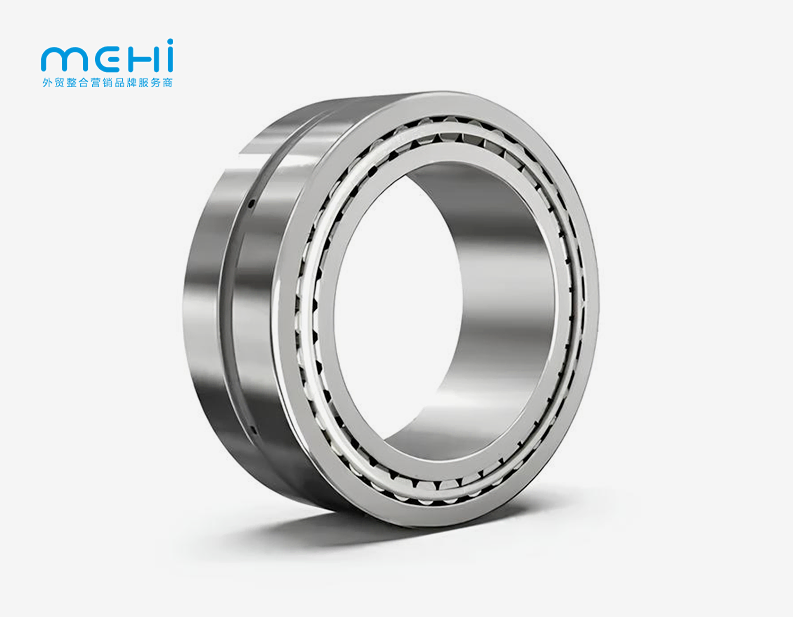

Generally, a single-row cylindrical roller ring consists of four major components as follows:

inner ring, outer ring, rollers, and cage.

2. Series Type: NU, NJ, N, NF series cylindrical roller bearing.

3. Advantages:The single-row cylindrical roller bearing is one separable type bearing. Generally, a single-row cylindrical roller ring consists of four major components as follows: inner ring, outer ring, rollers, and cage. The rollers are typically guided by two ribs of bearing ring .

This kind of bearing is easy to assemble,disassemble and applicable for high-speed rotation cases. So, compared with a normal radial ball bearing with same size, the cylindrical roller bearing is more suitable to the condition which require to bear higher radial load and higher impact resistance.

Normally,it is not used to bear an axial load. It is required the angle between the axes of its inner and outer rings is slight, generally less than 4'. Profiling of the rollers and the raceway generatrix can reduce the inclination requirement somewhat.

We manufacture single row cylindrical roller bearings are available in several designs. The main difference is the configuration of the flanges. The most popular designs are N design bearing,NU design bearing ,NJ design bearing,NUP design bearing.

4. Size range: Inter diameter:120-1320mm

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

Single Row Cylindrical Roller Bearing - High Performance Solutions for Heavy-Duty Applications

When you need reliable performance under extreme conditions, a Single Row Cylindrical Roller Bearing delivers exceptional results. These precision-engineered components highlight round and hollow rollers adjusted parallel to the revolution pivot, making most extreme contact region with raceways. This plan empowers you to handle overwhelming spiral loads whereas keeping up smooth, high-speed operation. Not at all like conventional ball heading, our round and hollow roller orientation minimize grinding and wear, guaranteeing your gear runs proficiently for expanded periods.

What Makes Our Cylindrical Roller Bearings Special?

Our heading stand out through prevalent designing and fabricating greatness. You get distinct bearing plans that streamline establishment and support strategies. Each bearing comprises of four basic components: inward ring, external ring, exactness rollers, and high-quality cage.

The round and hollow rollers are guided by two ribs on the bearing ring. This setup gives fabulous soundness amid operation. You can effectively collect and dismantle these orientation, making them culminate for high-speed revolution applications.

Compared to standard outspread ball heading of comparable estimate, our item offers predominant spiral stack capacity and affect resistance. This makes them perfect when you confront requesting operational conditions.

Available Series and Configurations

We manufacture multiple series to meet your specific requirements:

- N Series: Basic design for standard applications

- NU Series: Enhanced performance features

- NJ Series: Advanced load handling capabilities

- NF Series: Specialized configurations

Each series offers unique flange configurations to match your application needs. Our engineering team helps you select the optimal design for maximum performance.

Technical Specifications You Can Trust

Our bearings accommodate inner diameters ranging from 120mm to 1320mm. This extensive size range ensures you find the perfect fit for your equipment.

We use premium materials including:

- GCr15 steel for standard applications

- GCr15SiMn for enhanced durability

- G20Cr2Ni4A for specialized requirements

These materials provide excellent wear resistance and extended service life. Your investment delivers long-term value through reduced maintenance costs.

Why Choose MEHI Supply Chain Company?

As a high-tech enterprise, we specialize in designing and manufacturing high-reliability, long-lifespan bearings. Our facility features over 150 production equipment sets and 70+ testing instruments including CMM, metallographic microscopes, and friction torque testers.

This advanced equipment ensures every Single Row Cylindrical Roller Bearing meets stringent quality standards. We maintain annual production capacity of 30,000 sets of long-life mill bearings and 40,000 sets of high-precision thin section bearings.

Applications Across Industries

Our bearings excel in diverse applications:

Metallurgical Industry: Supporting blast furnaces, rolling mills, and steelmaking equipment where reliability is critical.

Mining Operations: Powering crushers, screens, and feeders that face continuous heavy loads.

Industrial Motors: Enabling high-speed operation in demanding gearbox applications.

Construction Equipment: Withstanding harsh environmental conditions while maintaining performance.

Performance Advantages You Experience

Tall stack capacity implies your gear handles heavier loads without compromising security. The plan minimizes contact, empowering high-speed operation whereas diminishing warm generation.

Superior strength interprets into less substitutions and lower upkeep costs. This cost-effective arrangement gives great return on speculation through expanded benefit life.

Get Expert Support Today

Our technical team provides comprehensive support throughout your bearing selection process. We help you identify the optimal Single Row Cylindrical Roller Bearing configuration for your specific application requirements.

Contact us at somyshare@gmail.com for technical consultation and product recommendations. Our experts are ready to discuss your project needs and provide customized solutions that exceed your expectations.