- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

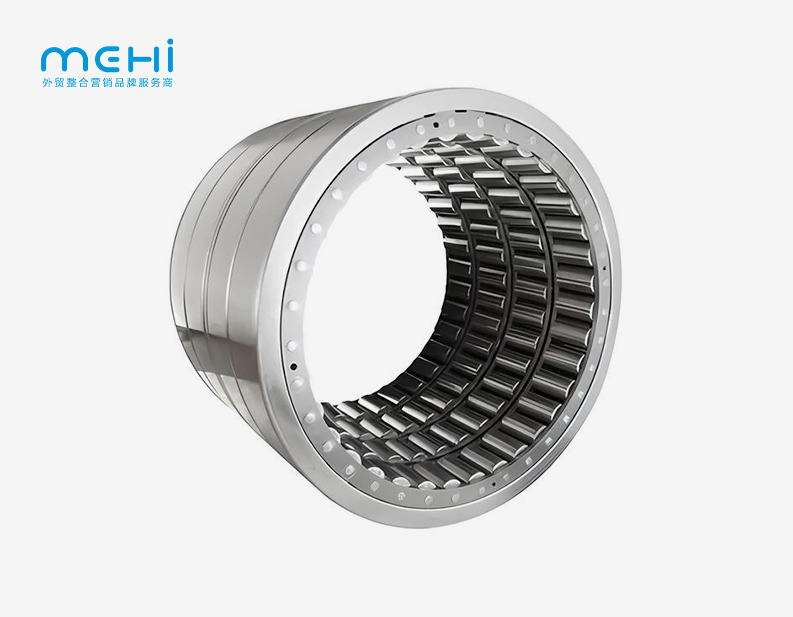

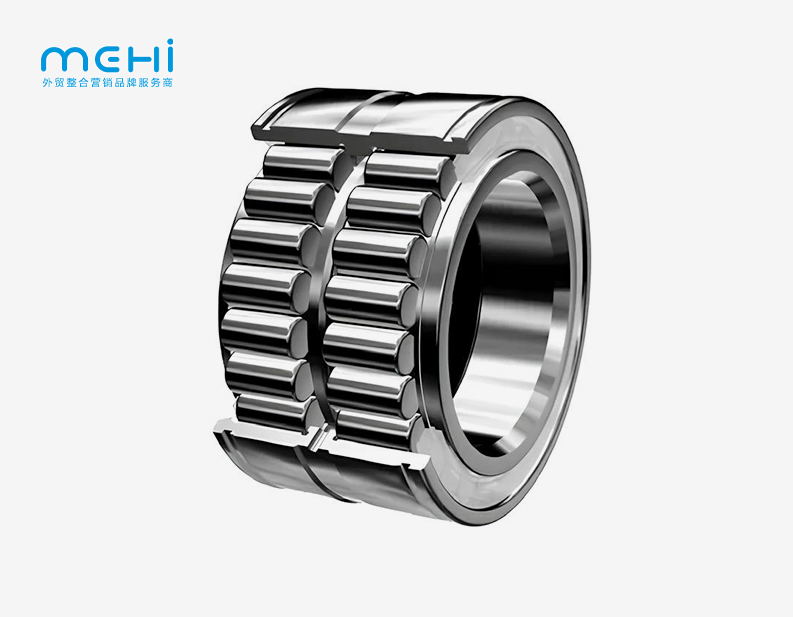

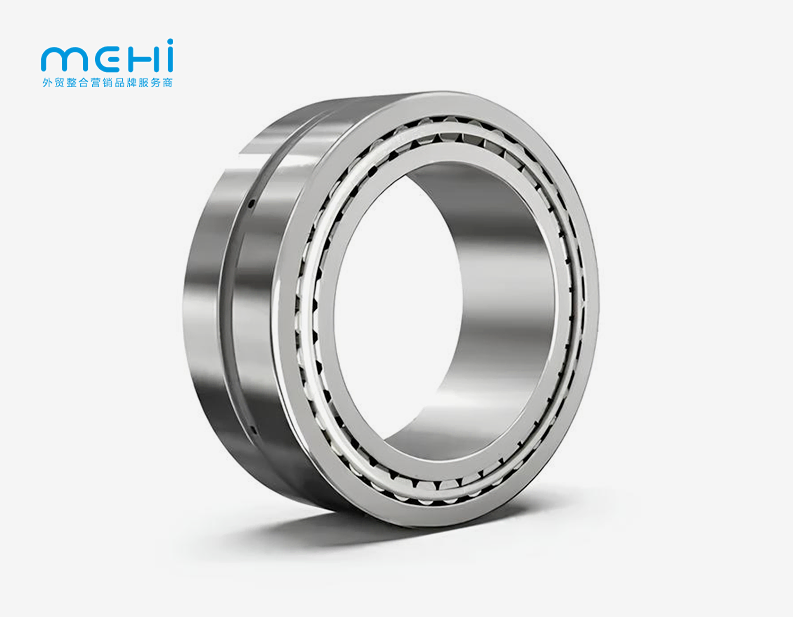

Four Row Cylindrical Roller Bearing

Internal diameter:90-1400mm

2. Type: FC series cylindrical roller bearing

FCD series cylindrical roller bearing

FCDP series cylindrical roller bearing

3. Application:

Four row cylindrical roller bearings are especially applied to rolling mills required high speed and precision, for example, wire mills, bar and shape mills, cold or hot sheet mills and cogging mills.

4. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

5. Cage:Brass solid cages or pin-type cages are mainly used in four row cylindrical roller bearings.

6. Feature:

Four row cylindrical roller bearings are the one of the main bearings for rolling mills. They are compact structures and high stiffness, and can carry high radial loads but not axial load. Because of inner rings with no rids, inner and outer ring subassembly ( with full set of rollers and cage) can be mounted respectively. Cleaning inspecting and dismounting are very convenient.

Four Row Cylindrical Roller Bearing: Superior Load Capacity for Heavy-Duty Applications

When your industrial equipment demands exceptional radial load capacity and unwavering reliability, you need a Four Row Cylindrical Roller Bearing that delivers outstanding performance. These specialized bearings feature four rows of cylindrical rollers arranged to provide maximum load distribution and operational efficiency. Unlike standard single-row bearings, this advanced design offers superior stiffness and compact structure, making it perfect for demanding applications where space optimization matters. Your equipment will benefit from reduced downtime and enhanced productivity with these precision-engineered solutions.

What Makes Our Four Row Roller Bearings Special?

Our orientation stand out through their inventive plan and remarkable fabricating quality. The compact four-row setup gives exceptional solidness whereas keeping up generally little measurements. You'll appreciate how these heading handle enormous spiral loads without compromising rotational accuracy.

The internal rings highlight no ribs, permitting inward and external ring subassemblies to be mounted independently. This plan makes cleaning, assessment, and getting off inconceivably helpful for your upkeep group. Your operations will encounter less downtime amid schedule upkeep methods.

Technical Specifications That Matter

Size Range: Our bearings accommodate internal diameters from 90mm to 1,400mm, ensuring we have the right fit for your specific application needs.

Series Options:

- FC series for standard applications

- FCD series for enhanced durability

- FCDP series for specialized requirements

Premium Materials: We use high-grade GCr15, GCr15SiMn, and G20Cr2Ni4A materials to ensure exceptional durability and performance under extreme conditions.

Cage Options: Choose between brass solid cages or pin-type cages, both designed to maintain optimal roller spacing and smooth operation.

Perfect Applications for Maximum Performance

Four Row Cylindrical Roller Bearing excels in rolling mill applications where high speed and precision are non-negotiable. Your wire mills, bar and shape mills will operate more efficiently with our four-row cylindrical roller bearings. Cold and hot sheet mills benefit significantly from the superior load handling capabilities.

Cogging mills particularly benefit from the compact design and high stiffness these bearings provide. The ability to handle extreme radial loads while maintaining dimensional accuracy makes them indispensable for your heavy-duty operations.

Why Choose MEHI for Your Bearing Needs?

MEHI Supply Chain Company brings over years of specialized experience in designing and manufacturing high-reliability, long-lifespan bearings. Our state-of-the-art facility houses more than 150 sets of main production equipment and 70 sets of advanced testing equipment.

Our quality control includes CMM, metallographic microscopes, roundness meters, and friction torque testers. We also employ UT, MT, and ET testing methods to ensure every bearing meets our stringent standards.

With an annual production capacity of 30,000 sets of long-life mill bearings, we're equipped to handle your volume requirements while maintaining consistent quality.

Installation and Maintenance Advantages

The ribless inner ring design allows for straightforward installation procedures. Your maintenance team can mount inner and outer ring subassemblies independently, reducing installation time and complexity.

Normal review gets to be easier with simple get to to all bearing components. The plan encourages intensive cleaning without total dismantling, amplifying bearing life and keeping up ideal execution.

Quality You Can Trust

Each Four Row Cylindrical Roller Bearing experiences thorough testing to guarantee dimensional resilience, pivotal and outspread runout meet industry-leading benchmarks. Our commitment to quality implies your hardware works dependably beneath the most requesting conditions.

Prepared to overhaul your gear with predominant bearing innovation? Contact us at somyshare@gmail.com to examine your particular prerequisites. Our specialized group will offer assistance you select the idealize item arrangement for your application needs.