- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

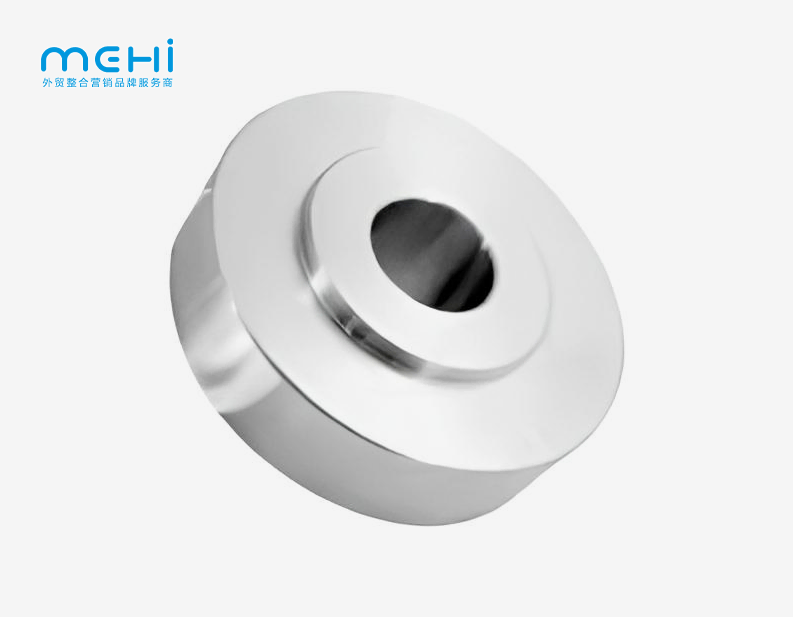

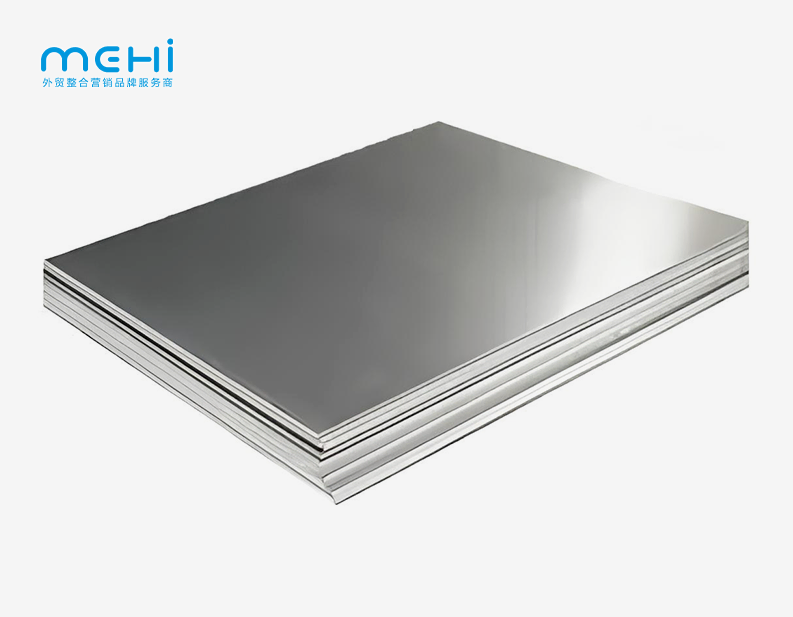

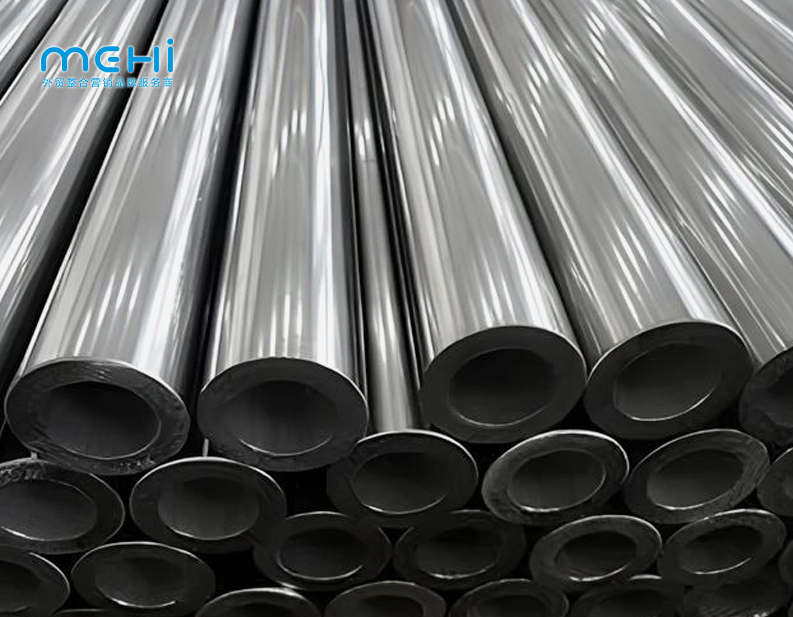

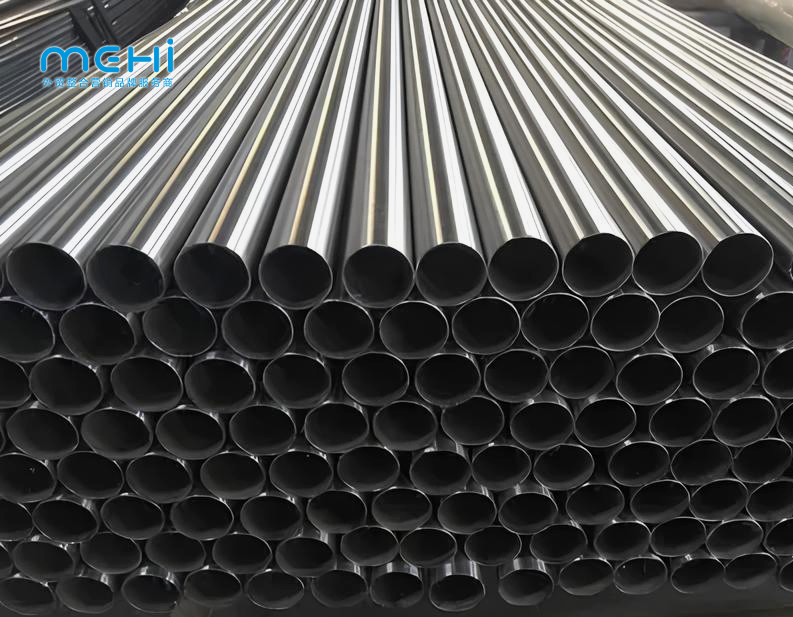

Nickel 200 Forgings: Premium Pure Nickel Components for Critical Applications

When you need exceptional corrosion resistance and superior mechanical properties for your most demanding applications, Nickel 200 Forgings deliver unmatched performance. These high-purity forged components contain a minimum of 99.6% nickel content, making them ideal for chemical processing, marine environments, and specialized industrial applications. Our expertly crafted forgings combine the natural benefits of commercially pure nickel with precision manufacturing to meet your exact specifications.

What Makes Our Forged Nickel Components Special?

Our manufactured nickel items stand out in the commercial center for a few key reasons. To begin with, the producing prepare upgrades the material's grain structure. This makes predominant mechanical properties compared to cast choices. You get progressed quality, superior weariness resistance, and upgraded reliability.

The producing prepare moreover dispenses with inner voids and porosity. This comes about in a denser, more uniform fabric structure. Your components will perform reliably beneath stretch and extraordinary conditions.

We keep up strict quality guidelines all through generation. Each piece experiences exhaustive assessment some time recently shipment. This guarantees you get components that meet or surpass your determinations.

Key Properties and Benefits

Immaculate nickel offers momentous erosion resistance in numerous situations. It performs especially well against caustic arrangements, decreasing acids, and unbiased salts. This makes it culminate for chemical handling gear and marine applications.

Temperature solidness is another major advantage. These materials keep up their properties over a wide temperature run. From cryogenic conditions to lifted temperatures, you can number on steady performance.

The fabric too gives great attractive properties. This makes it important for electronic applications and specialized attractive components. Its moo electrical resistance includes to its flexibility in electrical applications.

Applications Across Industries

Chemical preparing plants depend intensely on these manufactured components. Reactor vessels, warm exchangers, and channeling frameworks advantage from the predominant erosion resistance. The fabric withstands introduction to unforgiving chemicals that would rapidly debase other metals.

Marine applications speak to another major utilize case. Seawater contains forceful chlorides that assault most metals. Immaculate nickel stands up to this erosion viably, making it perfect for desalination gear and seaward platforms.

The pharmaceutical industry values these components for their virtue and cleanability. Preparing hardware made from Nickel 200 Forgings keeps up item judgment whereas standing up to contamination.

Food handling gear too benefits from these properties. The material's resistance to natural acids and simple cleaning make it reasonable for specialized nourishment generation situations.

Manufacturing Excellence and Quality Control

Our production process begins with carefully selected raw materials. We source only the highest quality nickel to ensure consistent composition. Strict incoming material inspection verifies chemistry and quality before processing begins.

The manufacturing handle itself requires exact temperature and weight control. Our experienced specialists screen each step to keep up ideal conditions. This consideration to detail comes about in prevalent grain structure and mechanical properties.

Advanced assessment hardware confirms dimensional exactness and fabric properties. We conduct chemical examination, mechanical testing, and non-destructive examination on each clump. This comprehensive approach guarantees you get components that meet your correct necessities.

Heat treatment processes are carefully controlled to optimize material properties. This step relieves internal stresses and enhances the material's performance characteristics.

Available Sizes and Specifications

We offer a comprehensive range of sizes to meet diverse application needs. Standard dimensions include diameters from 30mm to 600mm with maximum thickness up to 600mm. Custom sizes are available upon request to meet your specific requirements.

All products conform to major international standards including ASTM, JIS, AISI, GB, DIN, and EN specifications. This ensures compatibility with your existing designs and quality systems.

Each shipment includes Material Test Certificates according to EN 10204/3.1 standards. These documents provide complete traceability and verification of material properties.

Why Choose MEHI for Your Nickel Forging Needs?

When you select Nickel 200 Forgings from MEHI, you're selecting a accomplice committed to your victory. Our specialized skill and quality center guarantee you get components that perform dependably in your basic applications.

Ready to talk about your particular necessities? Contact us nowadays at somyshare@gmail.com to learn how our manufactured nickel components can upgrade your another extend.