- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

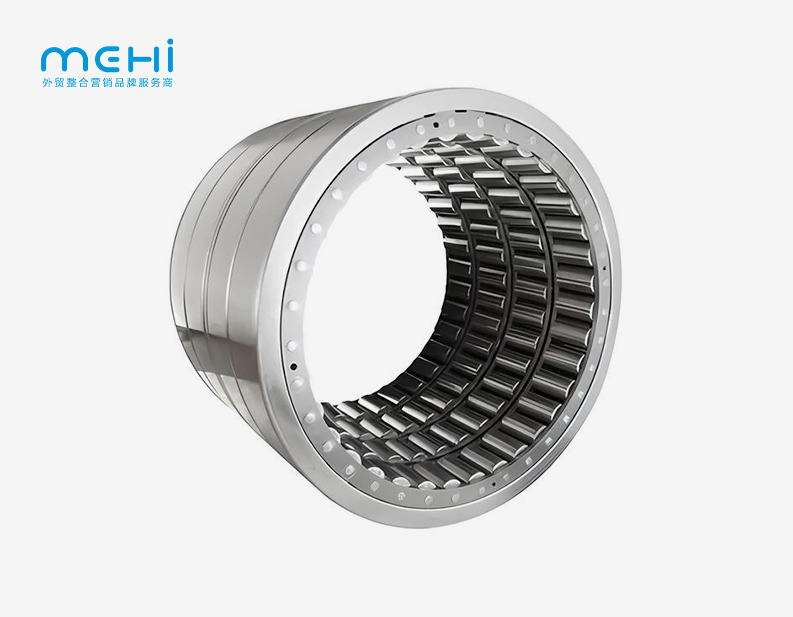

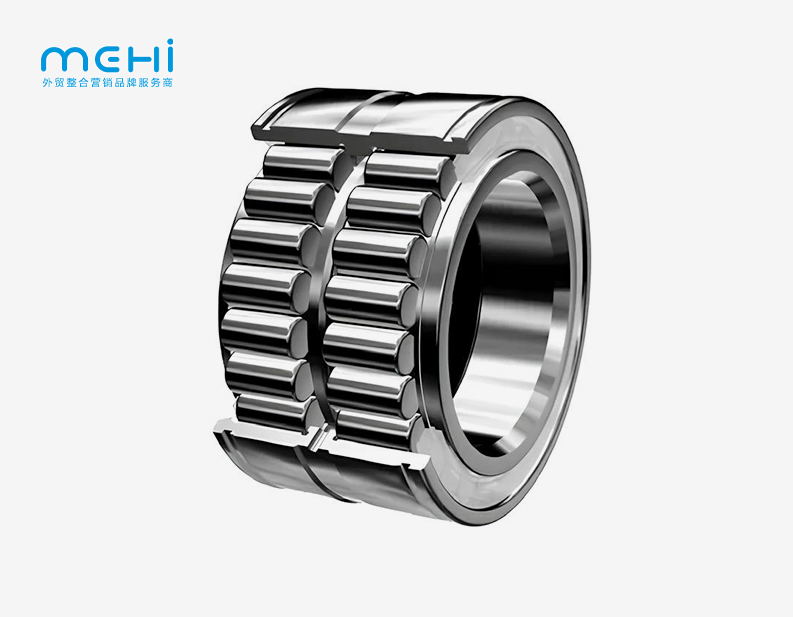

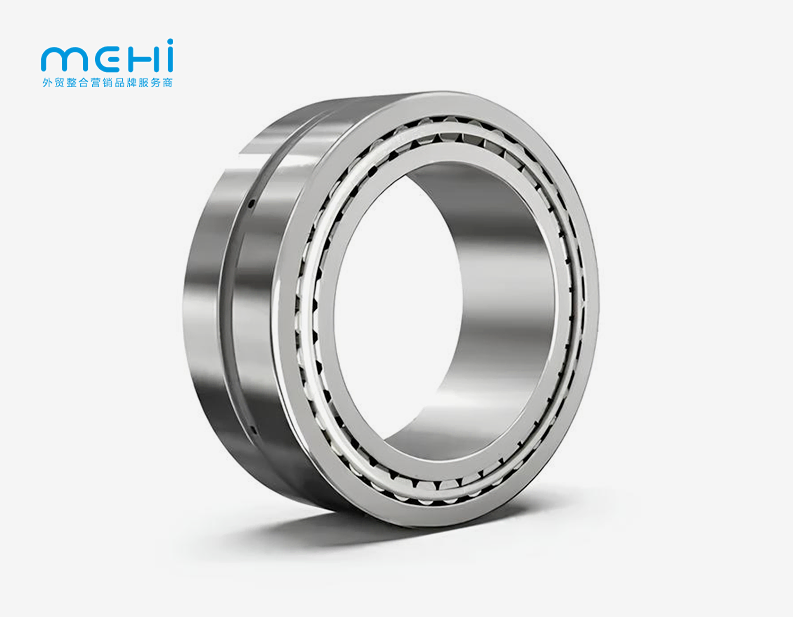

Four Row Tapered Roller Bearing

2. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

3.Features: Four row tapered roller bearings are the one kind of roll neck bearings, their radial and axial loading capacity are high, can carry heavy axail loads in two directions, and their radial loading capacity is 3 times heavier than single row tapered roller bearings.

4. Application: Four row tapered roller bearings mainly used in the working roll necks of hot or cold rolling mills, and roll neck of cogging mills. They usually clearance fit with roll necks to being mounted and dismounted conveniently.

5. Cage: Steel pressed cages are usually used in four row tapered roller bearings, and pin type cages are for large size taper bearings.

6. Advantage: We supplies many sizes of four row tapered roller bearings with integral radial shaft seals at both sides. They are available in several designs depending on bearing size as well as on the open (non-sealed) basic design.

Four Row Tapered Roller Bearing - Heavy-Duty Industrial Solution

When you need exceptional load-bearing performance for your heavy machinery, Four Row Tapered Roller Bearing delivers unmatched reliability. These precision-engineered components include four lines of decreased rollers that give prevalent stack dissemination and improved solidness. Whether you're working rolling plants, mining hardware, or large-scale mechanical apparatus, these orientation offer the vigorous execution your applications request. With their progressed plan and predominant materials, they guarantee ideal execution indeed in the most challenging situations.

Superior Load Capacity for Heavy-Duty Applications

You'll appreciate how these bearings excel in demanding industrial environments. The unique four-row configuration provides exceptional radial and axial load capacity - three times greater than single-row alternatives. This enhanced capacity makes them perfect for applications where standard bearings simply can't handle the stress.

Each bearing features tapered rollers arranged across four rows, distributing loads more evenly than conventional designs. This configuration reduces stress concentration points and extends bearing life significantly. The result is smoother operation and reduced maintenance requirements for your equipment.

Advanced Engineering and Materials

Our Four Row Tapered Roller Bearing employments premium materials counting GCr15, GCr15SiMn, and G20Cr2Ni4A steel grades. These high-quality materials guarantee great execution in cruel working conditions, counting tall temperatures and overwhelming loads.

The estimate run ranges from 120mm to 1320mm inward distance across, pleasing different gear prerequisites. Steel squeezed cages are standard for most sizes, whereas pin-type cages are utilized for bigger heading to guarantee ideal roller direction and maintenance.

Key Applications and Industries

These bearings shine in rolling mill applications, particularly for hot and cold rolling mills where extreme loads are common. Mining machinery operators rely on them for jaw crushers, impact crushers, and vibrating screens. The clearance fit design allows for convenient mounting and dismounting, reducing maintenance time and costs.

Large rotating equipment benefits from the enhanced stability and load distribution these bearings provide. Their robust construction handles the demanding conditions typical in metallurgical equipment, blast furnaces, and steelmaking machinery.

Enhanced Features and Benefits

The indispensably outspread shaft seals accessible on numerous plans give great assurance against defilement. This highlight amplifies bearing life and decreases upkeep necessities in dusty or damp environments.

Reduced contact is another critical advantage. The decreased roller plan minimizes inside grinding, driving to made strides effectiveness and lower working temperatures. This deciphers to vitality reserve funds and expanded hardware life for your operations.

Our heading experience thorough testing utilizing progressed hardware counting CMMs, metallographic magnifying lens, and grinding torque analyzers. This guarantees dimensional precision and execution consistency over our whole generation run.

Why Choose MEHI Supply Chain Company?

With over 150 sets of generation hardware and 70 sets of testing disobedient, we keep up strict quality control all through fabricating. Our yearly generation capacity incorporates 30,000 sets of long-life process heading, guaranteeing solid supply for your projects.

Each item meets industry-leading guidelines for dimensional resistance, hub and outspread runout, and matched projection deviation. This exactness fabricating guarantees ideal execution and amplified benefit life in your applications.

Contact Us for Your Bearing Solutions

Ready to upgrade your equipment with superior bearing performance? Our technical team can help you select the right Four Row Tapered Roller Bearing configuration for your specific application requirements.

Contact us at somyshare@gmail.com to discuss your project needs. We'll provide detailed specifications and recommendations to ensure optimal performance for your heavy-duty applications.