- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

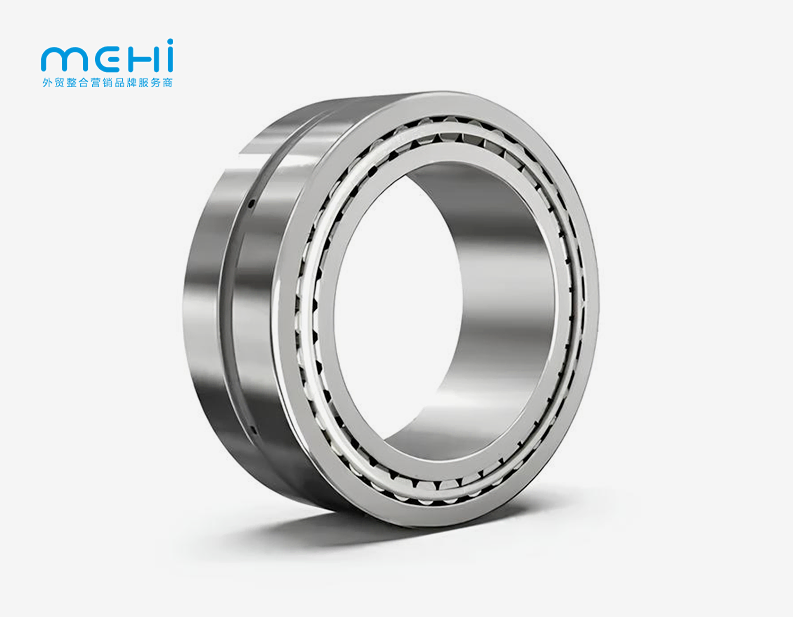

Double Row Tapered Roller Bearing

2. Application:rolling mills, gearboxes, hoisting equipment, mining machines, tunnelling machines.

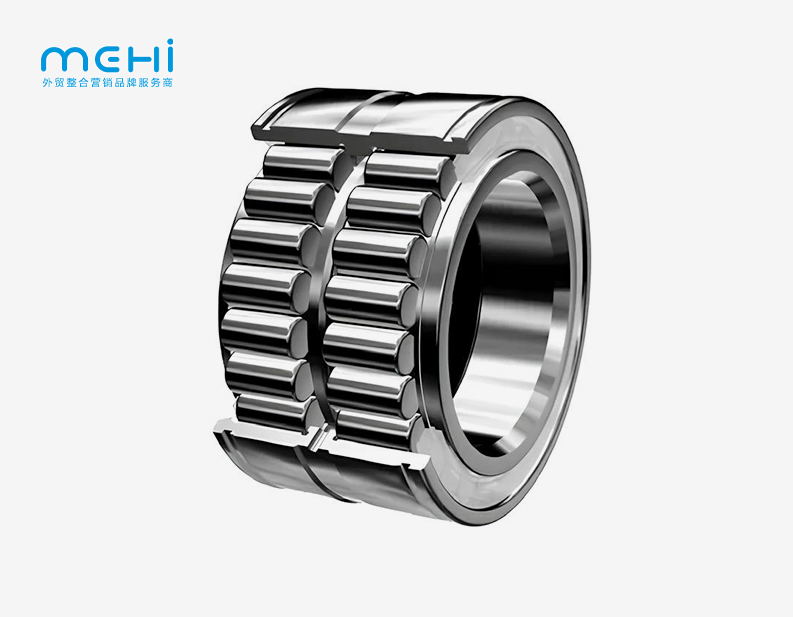

3. Advantage: Double row taper roller bearings have a small number of parts and high stiffness, and are easy to be mounted and dismounted, therefore, they are usually used in the applications with changes loads, such as reducers and coiling machines. The radial and axial clearance can be adjusted by changing the width of spacer between two inner rings.

4. Our double row tapered roller bearings are produced in two configurations and in several different designs:

The performance of type TDO bearing is the same as two single-two tapered roller bearings in back to back mounted.

Type TDI bearing is mainly used in roll necks with medium loads. This type of bearings have a cup spacer, and the clearance is asjustable

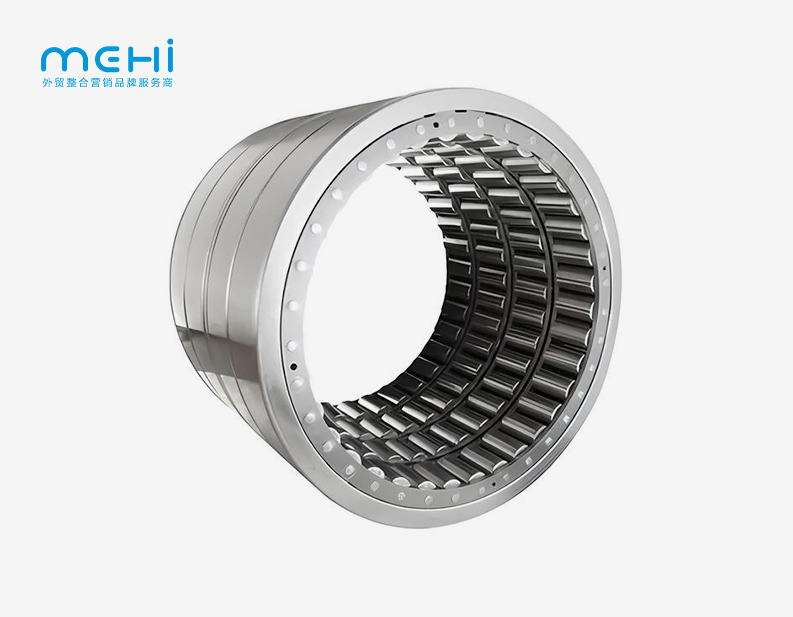

5. Size range: Inter diameter:150-1778mm

6. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

Double Row Tapered Roller Bearing - High-Performance Solution for Heavy-Duty Applications

When your industrial equipment demands reliable support for combined radial and axial loads, our Double Row Tapered Roller Bearing delivers unmatched performance and durability. These precision-engineered bearings are designed to handle bidirectional locating requirements while maintaining exceptional stiffness and load-carrying capacity. Your heavy machinery operations require components that won't fail under pressure, and our products provide exactly that reliability you need for continuous operation.

What Makes Our Double Row Tapered Roller Bearings Special?

Our orientation highlight a special plan that combines two columns of decreased rollers in a single lodging unit. This setup gives prevalent stack dissemination compared to single-row choices. You'll appreciate how these orientation limit pivotal relocation in both headings, making them culminate for applications where exact situating is critical.

The compact plan decreases the number of person components in your gathering. This rearrangements makes establishment and upkeep altogether less demanding for your specialized group. You'll moreover advantage from the flexible outspread and hub clearance highlight, accomplished by altering the spacer width between internal rings.

Available Configurations for Your Specific Needs

TDO Type Bearings

These bearings perform identically to two single-row tapered roller bearings mounted back-to-back. You'll find this configuration ideal for applications requiring maximum rigidity and load capacity.

TDI Type Bearings

Specifically designed for roll necks with medium load requirements, these bearings include a cup spacer for adjustable clearance. This design gives you the flexibility to fine-tune performance based on your operational demands.

Technical Specifications

- Inner Diameter Range: 150mm to 1,778mm

- Materials: GCr15, GCr15SiMn, G20Cr2Ni4A steel grades

- Load Capacity: Combined radial and axial loads

- Precision: High dimensional tolerance and runout control

Key Applications

Your Double Row Tapered Roller Bearing will excel in demanding industrial environments:

Rolling Mills: Handle the extreme forces generated during metal forming processes

Gearboxes: Provide reliable support for transmission systems under varying loads

Hoisting Equipment: Ensure safe lifting operations with dependable load management

Mining Machinery: Withstand harsh conditions in excavation and processing equipment

Tunneling Machines: Support continuous operation in challenging underground environments

Installation and Maintenance Advantages

You'll find these bearings remarkably user-friendly during installation. The separable design allows for independent mounting of inner and outer rings. This feature significantly reduces assembly time and minimizes the risk of installation errors.

Maintenance becomes straightforward with our product design. The adjustable clearance feature means you can compensate for wear without complete bearing replacement, extending service life and reducing operational costs.

Quality Manufacturing Process

At MEHI Supply Chain Company, we utilize over 150 sets of production equipment and 70 sets of testing instruments. Our comprehensive quality control includes CMM measurement, metallographic analysis, and friction torque testing. This rigorous approach ensures every bearing meets the highest industry standards.

Our annual production capacity reaches 30,000 sets of long-life mill bearings, demonstrating our commitment to meeting your volume requirements while maintaining quality consistency.

Why Choose Our Solution?

Your equipment deserves components that deliver consistent performance under the most challenging conditions. Our Double Row Tapered Roller Bearing products combine advanced metallurgy with precision manufacturing to provide the reliability your operations demand.

Ready to upgrade your equipment with superior bearing technology? Contact our technical team at somyshare@gmail.com to discuss your specific application requirements and receive personalized recommendations for your product needs.